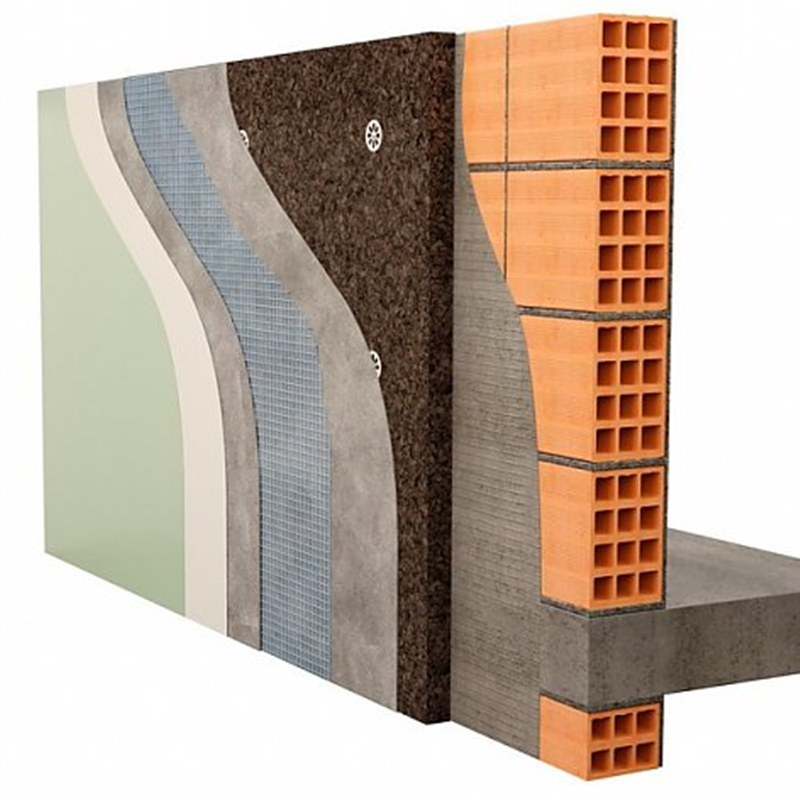

As global demand for energy-efficient buildings continues to rise, Exterior Insulation and Finish System (EIFS) technology has emerged as one of the most effective solutions for thermal insulation and exterior wall protection. Within these systems, Hydroxypropyl Methylcellulose (HPMC) has become an essential additive, significantly improving the performance of EIFS basecoat and adhesive mortars.

Industry experts highlight that the proper selection and use of HPMC is key to achieving the durability, workability, and insulation efficiency required in EIFS applications.

- Improving Adhesion and Mechanical Stability

EIFS mortars must adhere firmly to various substrates—EPS/XPS insulation boards, cement-based surfaces, or old walls. HPMC enhances adhesion by:

Providing uniform water retention for optimal cement hydration

Increasing bonding strength between mortar and insulation panels

Preventing premature drying that can lead to weak adhesion or delamination

Consistent adhesion is crucial for long-term system stability and resistance to weather changes.

- Superior Water Retention for Harsh Climates

EIFS projects often face challenges such as high wind, strong sunlight, or low humidity. HPMC’s excellent water-retention ability ensures:

Longer open time and workable life

Reduced risk of cracks and shrinkage

Longer-lasting hydration for improved strength development

This makes HPMC indispensable for EIFS installations in both hot and cold regions.

- Enhanced Workability and Spreadability

EIFS basecoat mortars must be easy to apply, smooth, and stable during troweling. HPMC contributes by:

Providing optimized viscosity and sag resistance

Enabling smooth application with less effort

Ensuring uniform thickness when embedding fiberglass mesh

Preventing mortar from sliding on vertical surfaces

Contractors benefit from faster installation, higher productivity, and more consistent finish quality.

- Reinforcing Crack Resistance and Durability

Crack resistance is essential for EIFS performance, especially due to thermal expansion and contraction. By regulating mortar rheology and hydration, HPMC helps:

Improve flexibility and deformation resistance

Minimize microcracks during curing

Enhance long-term weathering stability

Support overall system durability against wind, rain, and freeze–thaw cycles

These improvements significantly extend the lifespan of EIFS façades.

- Compatibility with Modern Additives and RDP

In EIFS formulations, HPMC works synergistically with Redispersible Polymer Powder (RDP) and other functional additives. The combination of HPMC and RDP brings:

Improved elasticity and impact resistance

Stronger bonding to insulation boards

Increased fatigue resistance under temperature fluctuations

Proper formulation design ensures high performance across all EIFS layers.

- A Growing Market Demand Driven by Global Energy Standards

With stricter building energy codes worldwide, EIFS systems are expanding rapidly in North America, Europe, the Middle East, and Asia. The market demand for high-grade HPMC tailored for EIFS mortars continues to grow.

Manufacturers are focusing on:

High-viscosity HPMC for superior water retention

Surface-modified grades for improved workability

Eco-friendly production to meet sustainability standards

The ongoing shift toward green construction further reinforces the importance of high-performance cellulose ethers.

Conclusion

HPMC plays a central role in the development of durable, high-performance EIFS mortars. From adhesion and crack resistance to workability and climate adaptability, HPMC delivers critical improvements that ensure stable, long-lasting exterior insulation systems.

As the global construction industry continues to push for energy-efficient and sustainable building solutions, the use of HPMC in EIFS mortars will remain a key technological advantage for material manufacturers and contractors worldwide.

Name: Cecilia.Wang

E-Mail:cecilia.wang@jtdf-rdp.com

Mobile:+86 190 3451 3486(Whatsapp)