In the ever-evolving world of construction, the demand for high-performance materials is continuously on the rise. Among these, tile adhesives play a crucial role in ensuring the durability and aesthetic appeal of tiled surfaces. Hydroxypropyl Methylcellulose (HPMC) is emerging as a game-changer in this domain, enhancing the performance and workability of tile adhesives. This article delves into the significance of HPMC for tile adhesive applications and how it is advancing performance and durability in modern construction.

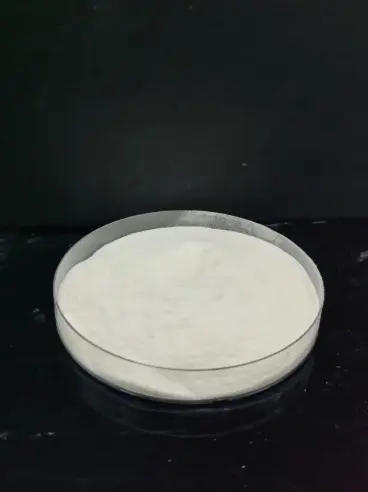

Hydroxypropyl Methylcellulose, commonly abbreviated as HPMC, is a cellulose-derived polymer that is widely used in construction materials. It is known for its exceptional water retention, thickening, and binding properties. These characteristics make HPMC an ideal additive for tile adhesives, improving their overall performance and ease of use.

HPMC significantly enhances the properties of tile adhesives, making them more effective and user-friendly.

Here’s how:

Water Retention: HPMC helps in retaining water in the adhesive mixture, ensuring better curing and adhesion. This is particularly important in dry environments where water can evaporate quickly, leading to poor bonding.

Improved Workability: The presence of HPMC in tile adhesives makes them easier to spread and handle. This results in a smoother application process, reducing the time and effort required for tile installation.

Enhanced Adhesion: By improving the bond strength between tiles and substrates, HPMC ensures that tiles remain securely in place over time, minimizing the risk of detachment or damage.

Increased Open Time: HPMC extends the open time of adhesives, allowing for more flexibility during tile installation. This means that tiles can be adjusted and repositioned without compromising the adhesive’s effectiveness.

The integration of HPMC in tile adhesives is transforming modern construction by offering several advantages that contribute to the durability and longevity of tiled surfaces.

In construction, durability is a critical factor that determines the lifespan and maintenance needs of a structure. HPMC-enhanced tile adhesives provide superior durability by:

Resisting Cracks and Shrinkage: The water retention and flexibility offered by HPMC prevent cracking and shrinkage, ensuring a long-lasting finish.

Withstanding Environmental Stressors: HPMC-based adhesives can endure various environmental conditions, including temperature fluctuations and moisture exposure, without losing their adhesive properties.

Supporting Heavy Loads: These adhesives provide a robust bond capable of supporting heavy tiles and loads, making them suitable for high-traffic areas and commercial applications.

Workability is a key consideration for construction professionals. HPMC enhances the workability of tile adhesives, making them more efficient and easier to use. The following aspects highlight the improvements in workability:

Ease of Mixing: HPMC ensures a consistent and smooth mixture, reducing lumps and making the mixing process straightforward.

Smooth Application: The enhanced viscosity and consistency of HPMC-based adhesives enable a seamless application, minimizing waste and ensuring uniform coverage.

Reduced Sagging: The thickening properties of HPMC help prevent sagging, allowing tiles to stay in place during the setting process.

The use of HPMC in tile adhesive applications is not just theoretical but has practical, real-world implications. Construction professionals have reported significant improvements in both the performance and ease of use of tile adhesives containing HPMC.

In a recent commercial building project, contractors opted for HPMC-enhanced tile adhesives to address the challenges of high foot traffic and environmental exposure. The results were remarkable:

Improved Efficiency: The construction team experienced faster installation times due to the improved workability and extended open time of the adhesives.

Long-Lasting Results: The tiled surfaces showed no signs of cracking or detachment even after several months of heavy use.

Cost Savings: The durability of the HPMC-based adhesives reduced the need for repairs and maintenance, leading to significant cost savings over time.

When selecting HPMC for tile adhesive applications, it’s essential to consider several factors to ensure optimal performance:

Quality and Purity: Choose high-quality HPMC that is free from impurities to achieve the best results.

Compatibility: Ensure that the HPMC is compatible with other components in the adhesive mixture to prevent any adverse reactions.

Concentration Levels: The concentration of HPMC can vary depending on the specific requirements of your project. Consult with manufacturers or experts to determine the ideal concentration for your needs.

In conclusion, HPMC is revolutionizing the tile adhesive industry by offering unparalleled enhancements in performance, durability, and workability. As construction demands continue to evolve, the role of HPMC in advancing tile adhesive applications will only grow in significance. Whether you’re working on a residential renovation or a large-scale commercial project, incorporating HPMC into your tile adhesive formulations can lead to superior results, ensuring that your tiled surfaces stand the test of time.

By understanding the benefits and applications of HPMC, construction professionals can make informed decisions that enhance the quality and longevity of their projects. Embrace the advancements that HPMC offers and experience the difference in your next construction endeavor.

Name: Cecilia.Wang

E-Mail:cecilia.wang@jtdf-rdp.com

Mobile:+86 190 3451 3486(Whatsapp)