As modern construction materials continue to evolve, Hydroxypropyl Methylcellulose (HPMC) has become an essential functional additive in dry-mix mortars. Known for its excellent water retention, thickening ability, film formation, and workability improvement, HPMC plays a critical role in tile adhesives, wall putties, gypsum-based products, EIFS mortars, and self-leveling compounds.

However, to fully achieve its intended performance, HPMC must be used correctly. Recent industry analyses highlight several important precautions that manufacturers and contractors should follow to ensure consistent product quality and optimal construction results.

- Avoid Direct Addition to Hot Water — Ensure Proper Dispersion

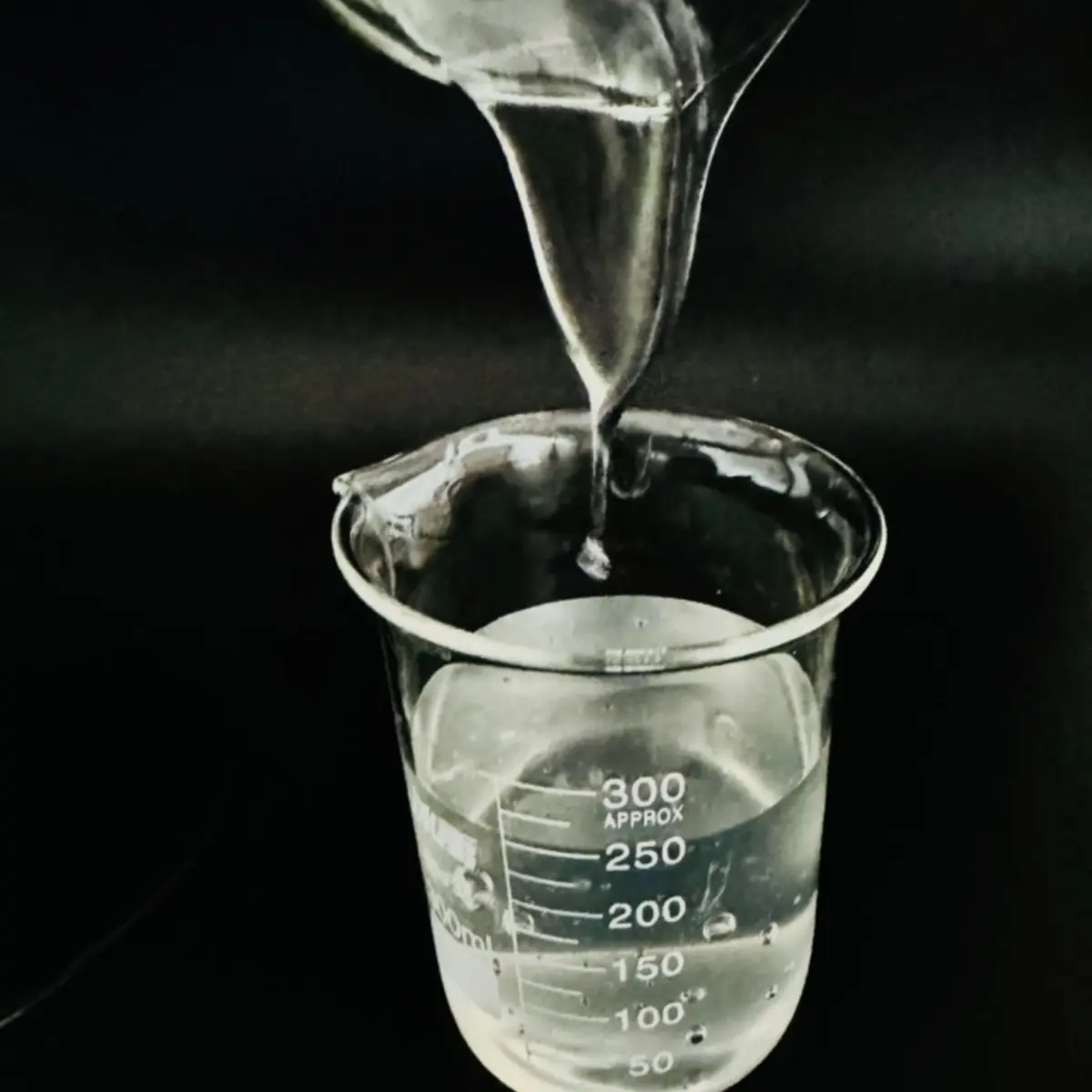

One of the most common issues in mortar production is improper dispersion of HPMC. If added directly to hot water or mixed unevenly, HPMC may form lumps, resulting in poor viscosity development and inconsistent performance.

To ensure proper dispersion:

Dry blend first: Mix HPMC with all dry powders before adding water.

Avoid adding HPMC to water above 60°C, which may cause gelation and clumping.

In liquid formulations, HPMC should be sprinkled slowly into vigorously stirred water to avoid agglomeration.

Correct dispersion is the foundation for HPMC to deliver its full water-retention and thickening effects.

- Control Dosage to Prevent Excessive Thickening or Poor Workability

Although HPMC greatly improves mortar performance, excessive dosage can cause:

Mortar becoming too thick or sticky

Difficulty in troweling and finishing

Excessively long open time

Increased material cost

Typical recommended dosages include:

Wall Putty: 0.2%–0.4%

Tile Adhesive: 0.2%–0.45%

Gypsum-Based Plasters: 0.1%–0.3%

Choosing the right viscosity and substitution level is crucial to achieving balanced performance.

- Check Compatibility with Cement, Gypsum, and Other Additives

HPMC performance can vary depending on the components in the mortar system. Factors influencing compatibility include:

Cement mineral composition

Gypsum retarders or accelerators

Redispersible polymer powder (RDP)

Plasticizers, defoamers, air-entraining agents

Incompatibility may cause:

Abnormal viscosity increase

Bleeding or segregation

Reduced early bonding strength

Unstable mortar behavior

A full compatibility test is essential before launching new formulations.

- Ensure Proper Storage — Moisture Protection is Critical

HPMC is hygroscopic and can easily absorb moisture, leading to:

Caking

Reduced viscosity

Poor dispersibility

To maintain product quality during storage:

Store HPMC in a cool, dry, and well-ventilated place

Keep packages sealed tightly

Avoid direct sunlight or high-temperature environments

Keep away from strong acids or alkali chemicals

Proper storage ensures long-term stability and consistent performance.

- Adjust Formulation Based on Climate and Job-Site Conditions

Environmental factors have a significant impact on HPMC behavior:

Hot or Dry Weather

Mortar dries too quickly

Cracking risk increases

Higher water-retention grade HPMC is recommended

Cold or Humid Conditions

Excessively long open time

Slower strength development

Medium-viscosity or lower water-retention grades may be more suitable

Highly Absorbent Substrates (AAC blocks, lightweight bricks)

Improve water retention

Increase bonding strength

Use higher viscosity or modified HPMC

A flexible formulation strategy ensures consistent results across varying conditions.

- Environmental & Safety Considerations — Focus on Low-VOC & Dust Control

As sustainability becomes a key priority in global construction, manufacturers must consider:

Compliance with low-VOC requirements

Dust reduction during mixing

Use of HPMC grades with environmentally friendly production processes

Worker safety during handling and batching

Eco-friendly cellulose ethers not only protect the environment but also enhance company brand value.